This guide will help you choose the right replacement spindle for your trailer axle by walking you through the same process we use in-house at Axle Spindle when selecting heavy-duty semi-trailer spindles that require a sleeve for our customers. Picking the correct spindle and sleeve combo is key to a smooth, successful install.

Please note: This guide applies only to semi-trailer replacement spindles offered by Axle Spindle Inc.

Follow the steps below to pick your spindle and sleeve straight from our shop page.

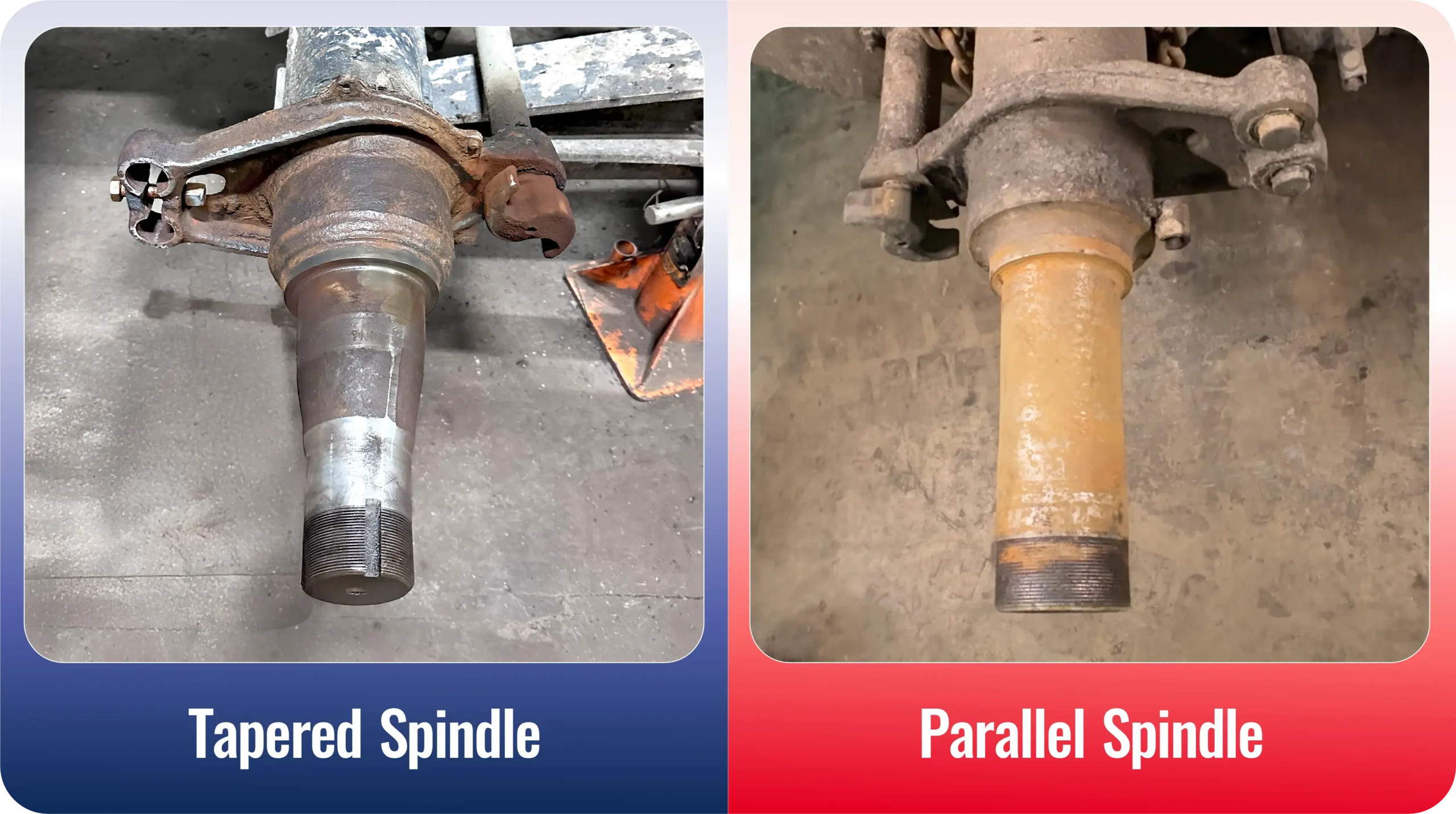

Step 1: Identify the Spindle Shape

Begin by examining your OEM spindle to determine its shape. Check whether it is Tapered or Parallel. This is critical because the shape dictates the type of spindle you need:

- Tapered spindle: Has a gradually decreasing diameter along its length. This design requires two different-sized bearings—one for the inner and one for the outer position.

- Parallel spindle: Maintains the same diameter at both bearing locations, so it uses the same bearing size for both the inner and outer sides.

You can check the compatibility of our Parallel and Tapered Semi-Trailer Spindles with the associated parts below:

Parallel Trailer Spindles

The Semi-Trailer Parallel Spindle models 75, 85, and 115 are compatible with:

- Outer bearing set 415

- Timken inner bearing set 415

- National seal 370065A

- Pro-Torque Lock nut 447-4723

Tapered Trailer Spindles

The Semi-Trailer Tapered Spindle models 75, 85, and 115 are compatible with:

- Outer Bearing 413 (HM212049-HM212011)

- Inner bearing 414 (HM218210 & HM218248)

- National Seal 370025A

- Pro-Torque Lock nut 447-4743

Now that you’ve identified whether a tapered or parallel spindle is needed for your trailer axle, the next steps will help you determine which spindle model—75, 85, or 115—is the right fit.

Step 2: Measure the Axle Tube’s Outside Diameter

You can measure the outside diameter using a vernier caliper or measuring tape, as explained below:

Using a Vernier Caliper

- For the most accurate measurement, use a vernier caliper with long jaws as shown in the image.

- Open the caliper jaws and place them around the outside of the axle tube, ensuring they are perpendicular to the tube’s axis to avoid skewed measurements.

- Close the jaws gently until they snugly contact the tube’s outer surface, then read the measurement displayed on the caliper scale.

- This gives you the outside diameter directly.

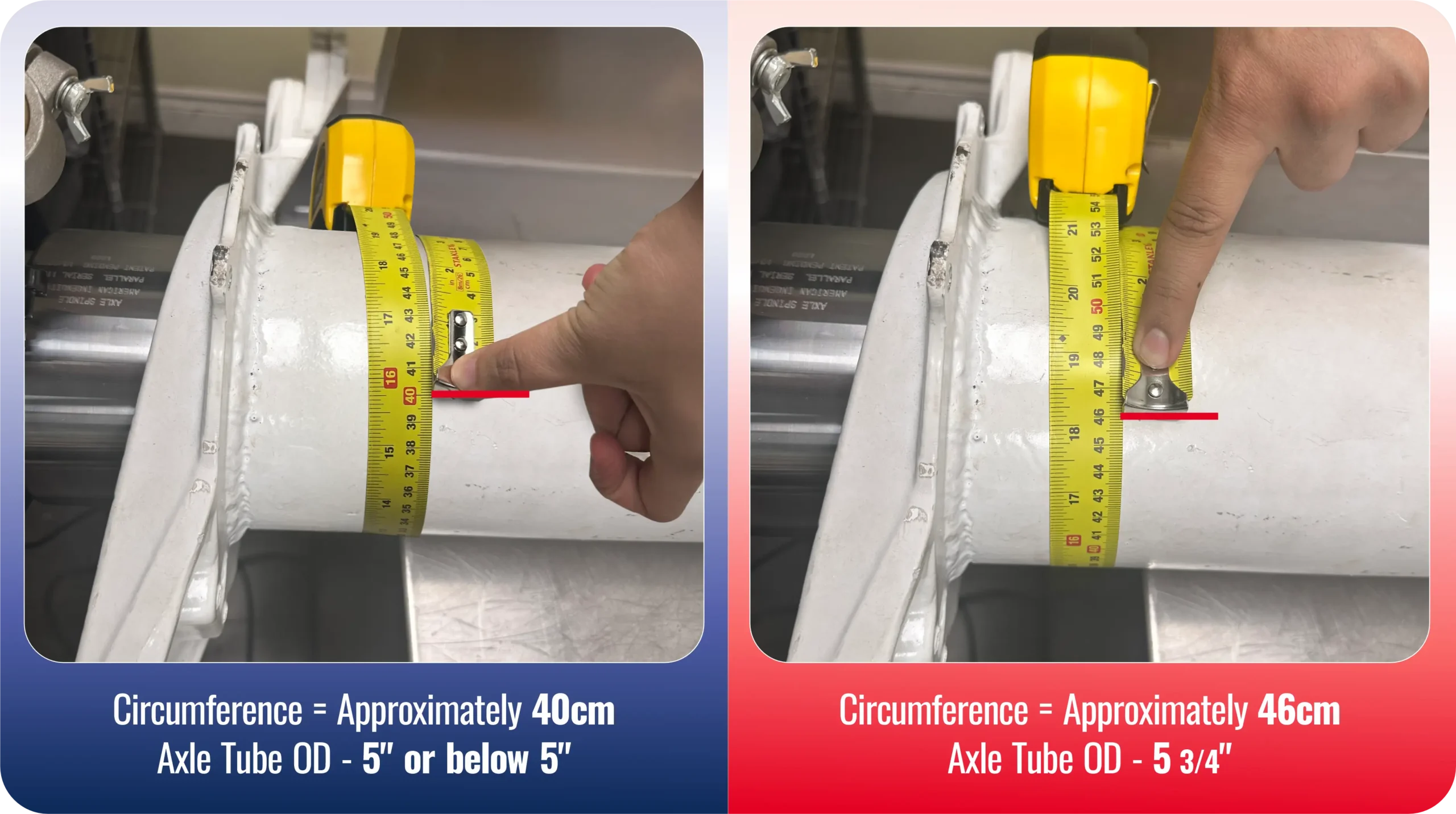

Using a Measuring Tape

- If you don’t have a vernier caliper you can use a flexible measuring tape to measure the circumference of the axle tube.

- Wrap the measuring tape tightly around the outside of the axle tube, ensuring it lies flat and isn’t twisted. Make a note of the circumference measurement where the tape completes a full circle (in centimeters).

- To estimate the outside diameter, use the circumference measurement and the formula:

- Diameter = Circumference ÷ π (approximately 3.1416)

For example:

If the circumference is approximately 40 cm:

- Axle Tube OD = 40 ÷ 3.1416 = 12.73 cm (127.3mm)

- Axle tube OD will be 5″ or below 5″

If the circumference is approximately 46 cm:

- Axle Tube OD = 46 ÷ 3.1416 = 14.64 cm (146.4mm)

- Axle tube OD will be 5 ¾″

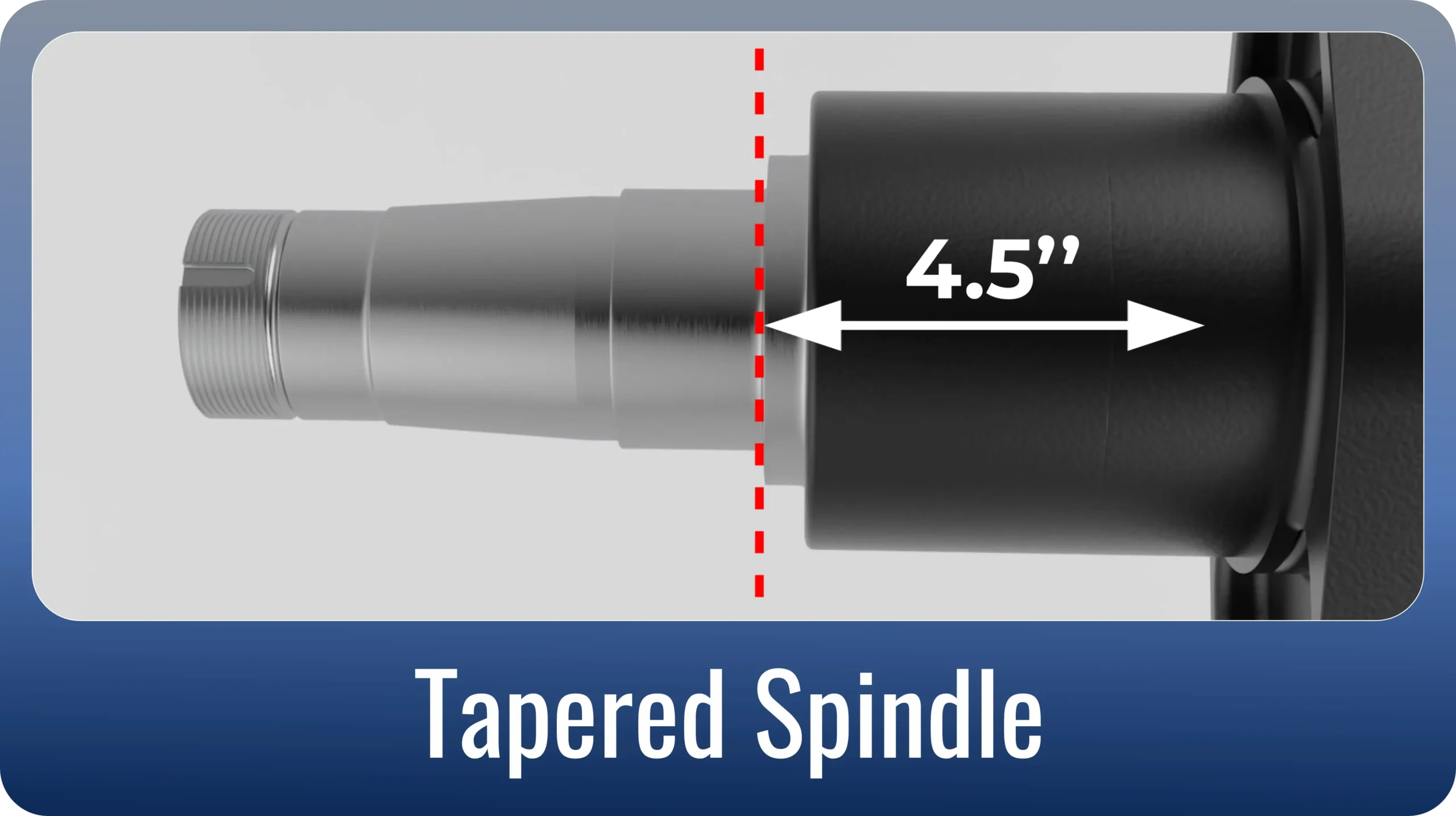

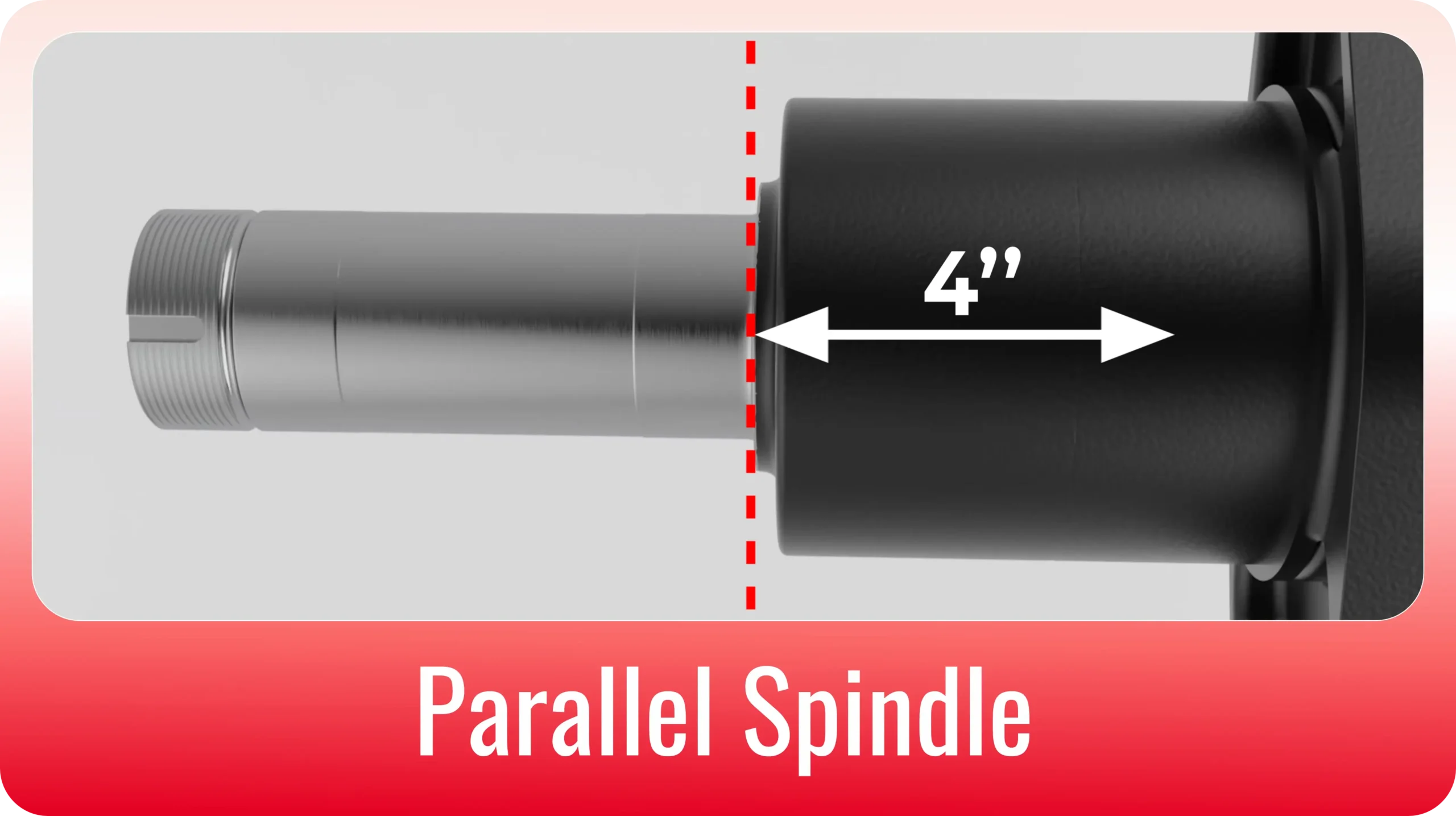

Step 3: Cut the Spindle

Depending on the spindle shape, cut it at the appropriate length from the face of the seal:

Tapered spindle: Cut 4.5 inches from the face of the seal.

Parallel spindle: Cut 4 inches from the face of the seal.

Step 4: Calculate the Inside Diameter of the Axle Tube

After cutting the spindle, measure the wall thickness of the axle tube as shown in the image below.

To calculate the inside diameter:

- Subtract twice the wall thickness from the outside diameter.

- ID = OD − (2 × WT)

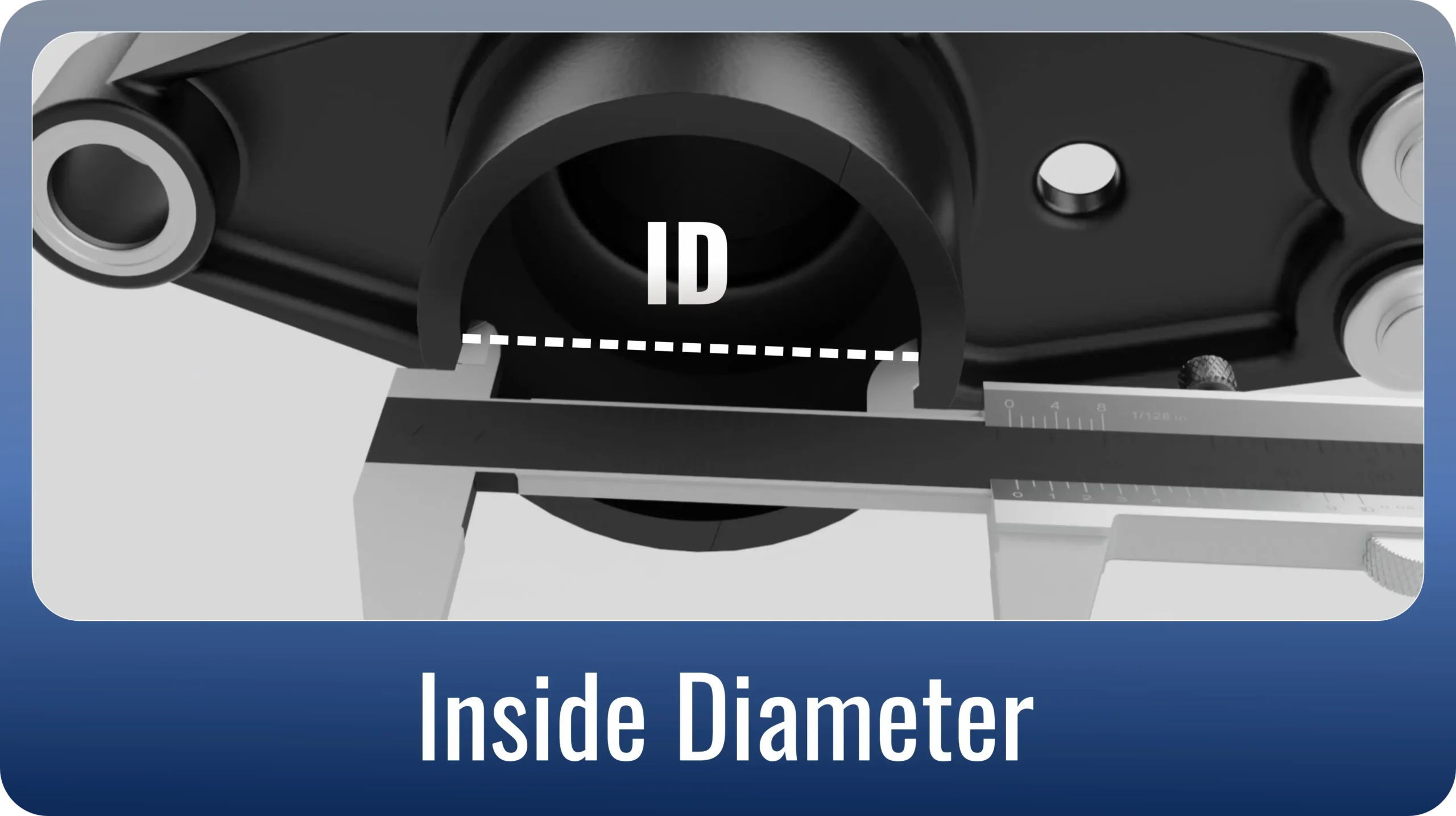

- For added accuracy, directly measure the inside diameter using a vernier caliper to verify your calculation as demonstrated in the image below:

Step 5: Match the Spindle Model

Using the inside diameter of the axle tube, select the appropriate spindle model:

| Axle Tube Inside Diameter (ID) Range | Suitable Semi-Trailer Spindle |

| 84 – 94.75 mm | Semi-Trailer Spindle 75 |

| 94.75 – 105 mm | Semi-Trailer Spindle 85 |

| 122 – 130 mm | Semi-Trailer Spindle 115 |

Step 6: Select the Sleeve

The sleeve’s outside diameter (OD) is the axle tube’s inside diameter (ID). For example, if the axle tube’s inside diameter is 96.75 mm, choose a sleeve with an OD of 96.75 mm.

Axle Tube ID = Sleeve OD

Pro Tip: Before installing the sleeve, clean the inside of the axle tube using a tool like the Makita GS5000 5″ straight grinder. This ensures a smooth surface for the sleeve. The sleeve should have a slip fit, meaning it slides easily into the axle tube bore without requiring force.

Example: Selecting the Correct Spindle and Sleeve

Let’s say your OEM spindle shape is Tapered, and the axle tube’s inside diameter(ID) measures 124.50 mm. Based on the measurements:

- Select a sleeve with an OD of 124.50 mm.

- Choose the Semi-Trailer Tapered Spindle 115 (because ID lies between 122 to 130 mm).

You’ve Got This

By following these steps—identifying the spindle shape, measuring the axle tube, cutting the spindle, calculating the inside diameter, and matching the sleeve and spindle model—you can confidently select the right replacement spindle for your heavy-duty trailer axle. Always double-check measurements and ensure a snug, proper, slip fit for the sleeve to guarantee a secure and reliable installation.

A Quick Note Before You Go:

This guide is meant to help you select the correct trailer spindle—not walk you through the full installation process.

Need help with your trailer spindle installation? Check out our step-by-step video guides for:

Still have questions about spindle selection or installation? We strongly recommend our training program, which is designed to walk you through everything, with clear, hands-on guidance from our experts.

For immediate support, don’t hesitate to reach out to our team—we’re here to help every step of the way.

Share